Turbocharger Oil Leak

Oil may leak from the turbine for a variety of reasons: the air filter or air intake system becomes clogged, the engine oil begins to stick or it did not initially match the temperature regime, the oil ducts of the engine become caked.

More complicated reasons are impeller breakage, considerable wear of turbine bearings, turbine shaft jamming, due to which the impeller does not rotate at all.

However, in most cases oil leakage from the turbine is caused by simple repair problems, most of which many car owners are quite capable of fixing on their own.

Why is oil coming out of turbo

Turbo is leaking oil usually because the stop rings, which keep the oil out of the turbine, wear out and start to leak. This happens because the pressure in the unit drops, and in turn, the oil from the turbine presses to where there is less pressure, that is, outward.

Causes of engine oil leakage from the turbine of the car

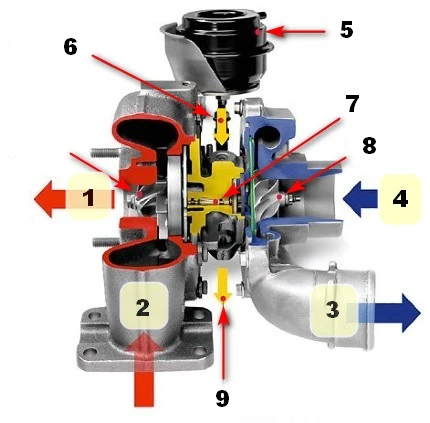

Principle of turbocharger operation: 1. Exhaust gas outlet; 2. Exhaust intake; 3. Compressed output; 4. Air intake to the turbocharger; 5. Aneroid box; 6. Oil supply; 7. Rotor shaft; 8. Turbocharger wheel; 9. Direction of oil under pressure;

There are quite a few reasons why a situation may arise when oil is coming out of turbo.

We will provide a whole list of possible problems, and then tell you why this could happen and what is worth doing.

- the air filter is clogged

- oil has become unsuitable for operation

- clogged oil system

- turbine impeller is damaged

- wear of the turbocharger bearings

- wear of elements of the cylinder-piston group

- clogged crankcase filter

Clogged air filter

A filter that hasn't been changed for a long time is the simplest situation, which, however, may become the cause of the mentioned problem. You should check the filter for clogging and replace it, if necessary.

In winter, instead of or together with clogging, in some cases, its freezing is possible (for example, in conditions of very high humidity). In any case, it is necessary to check the condition of the filter, as well as, together with it, the cleanliness of its box and the intake pipe.

Bad Engine Oil

It may have become unsuitable if the oil change period has long passed or if an oil unsuitable for a given engine was initially filled (manufacturer's tolerances were not observed or engine characteristics were not taken into account).

A turbocharged engine is very sensitive to oil quality, and also likes more heat-resistant oil. In addition, it is better to reduce the interval of its replacement by 10% of the prescribed by the regulations. This will increase the life of both the engine and the turbine.

Fouled oil ducts

High thermal loads, infrequent oil changes and its incompatibility with the turbocharged engine lead to coking of the oil ducts, clogging of oil pipes and the turbine itself. As a result the oil light may light up and oil may leak from the turbine. Besides, oil may also start to flow into the intercooler (intake manifold), since there is a pressure difference, due to which the oil actually «spits out» into it.

Impeller failure

Turbine impeller wear

Wear and malfunction of the turbine impeller can occur both due to natural causes and as a result of mechanical damage or the quality of the used engine oil. As a rule, impeller failure and oil leakage in a car turbine just for that reason could be preceded by a significant backlash of the impeller shaft and noise during turbine start-up.

Turbine bearing wear

When the bearings are worn, not only will oil leak from the turbine, but there will be a significant flow of oil, which will be much higher than normal. If the bearings are not replaced on time, then the shaft will seize and the turbine will fail completely. Therefore, if the cause of oil leakage from the turbine refers to its malfunction, you will need a comprehensive diagnosis and repair.

Worn parts of the cylinder-piston group (CPG)

Clogged breather filter

With such a problem, it is possible that the exhaust gases break into the sump of the crankcase and create increased pressure there. This is especially aggravated if the crankcase gas ventilation is not working properly or not fully. Accordingly, gravity oil drainage is impeded, and the turbine simply pushes it out of the system through weak seals.

Clogged breather filter

In the crankcase ventilation system there is a metal filter that does not let oil into the intake manifold, so if it is clogged (including as a result of wear of the cylinder head and high oil flow into the intake system) oil can go both from the turbine and into the intake system. Therefore, together with checking the efficiency of crankcase gas ventilation (including the valve located on the valve cover) it is worth checking the condition of the said filter.

How can you fix engine oil leakage from a turbine?

The choice of one or another troubleshooting solution directly depends on what exactly caused the problem. However, let's list the most likely options, from simple to more complex.

Learn what causes a turbo oil leak: video

- Change the air filter, it is inexpensive, but very important for the stable operation of the engine.

- Check the condition of the filter body inside and clean it from dust.

- Disconnect the pipe that goes from the filter housing to the manifold to see if there is any oil in it. This will tell you if there is a problem with the crankcase system (there will be traces of oil). Then be sure to reassemble everything properly.

- Make sure the oil in your engine meets the manufacturer's tolerances. To do this you can find out what kind of oil you use, as well as determine the engine oil (if you change it by yourself you must have a canister, and if you change it at service center, the service technician should write in the service book or mark on the label under the hood).

- It is necessary to control the condition of oil pipes and also condition of a shaft, impeller and bearings periodically, and not to allow their significant backlash. At the slightest suspicion of malfunction it is necessary to perform diagnostics.

- Check the crankcase ventilation. Pay attention that the condensate formed in the exhaust manifold due to temperature difference is often mistaken for oil, because the moisture mixed with dirt turns black. You have to be careful, and make sure that it really is oil.

- If there is leakage into the engine intake or exhaust system, it also makes sense to check the condition of the gaskets. Over time and under the influence of high temperatures it can wear down considerably and fail.

FAQ:

-

What happens when a turbine leaks oil?

Oil leaks can in seconds lead to serious damages of bearing systems.

-

Can a leaking turbo be fixed?

The simplest way to fix this is to change the turbocharger (sometimes the change of turbocharger is not enough and additional repairs are needed).

-

How much does it cost to fix a turbo oil leak?

It costs approximately $430 — $500 to fix turbo oil leak: $130 on parts and $300 — $370 labor costs.

-

Can I drive a car with a leaking turbo?

Yes, you can drive for a while. But to prevent engine failure we recommend you to visit the service as soon as possible.