Audi A6 2.5 TDI V6 T-belt & High Pressure Fuel Pump Belt Replacement

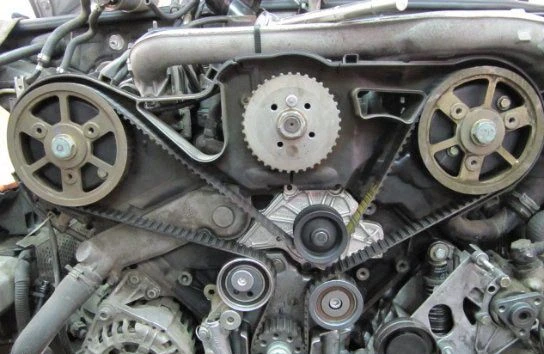

In this article, we will focus on replacement details of timing belt and fuel pump belt, patient is Audi A6 2.5 TDI V6 2001. Automatic transmission (Mot. AKE). The work sequence described in this article is suitable for replacing the timing belt and pump belt on engines AKN; AFB; AYM; AKE; BCZ; BAU; BDH; BDG; BFC. Discrepancies may occur when working with vehicles of different release years, but most differences arise when handling body parts.

Tools:

- Base 3036;

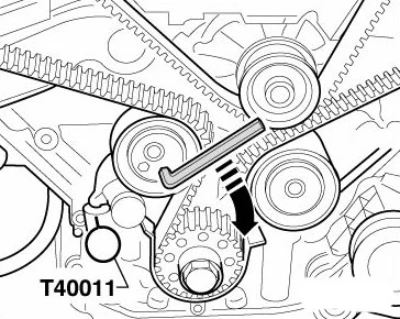

- Lock T40011;

- Double-ended releaser T40001;

- Bearing bolt 3242;

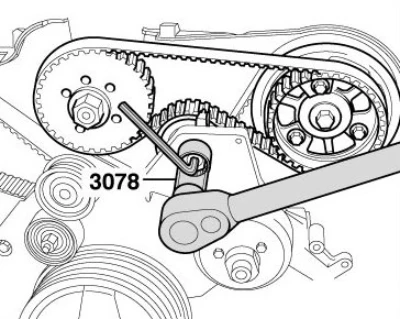

- Nozzle 22 3078;

- Camshaft Lock 3458;

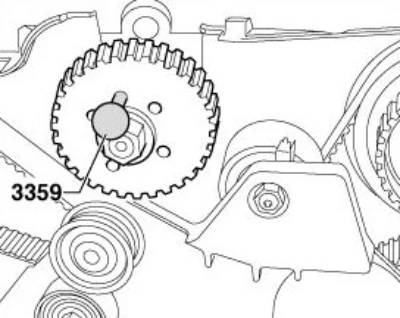

- Diesel Pump Lock 3359;

General work sequence

Let’s start. First, remove the upper and lower engine protection,

as well as air filter duct, do not forget to remove intercooler pipes coming from the intercooler radiator. Then, unfix front engine mount from intercooler pipe. Unscrew bolts securing the air conditioning radiator, take away radiator, disconnecting from the oil lines is not necessary. Unscrew bolts securing the automatic transmission (AT) oil lines, take the lines away to the body center. Disconnect the cooling system pipes, discharge the coolant, do not forget to prepare container. Disconnect electrical connectors and chips from the headlights, remove bonnet cable. Unscrew the front panel bolts and remove with a radiator. Do not put the radiator in the maintenance position, as you need more spare space exercising this work. That's why we recommend spending 15 minutes to drain the coolant, as well as to remove the radiator with the headlights.

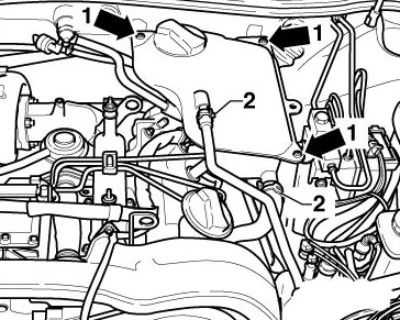

Getting started on the right side of the engine, remove the air intake duct that leads to the air filter.

Now disconnect the meter connector and remove the air filter cover.

The duct is removed between the intercooler and turbocharger.

The fuel filter is removed without disconnecting the hoses and sensor bearings, just move them aside. Dismiss the plug of right cylinder head camshaft.

Take off the plug at the back of the right camshaft.

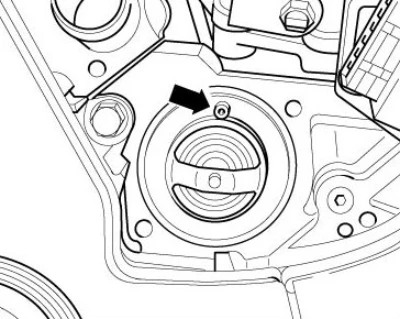

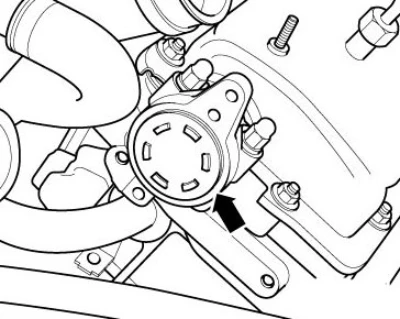

When removing, the plug will dissolve, remove the plug carefully so as not to spoil the sealing edge of the grounding (arrow). The easiest way to remove the plug is pre-trial and hooking with L-shaped tool. Remove by shaking in different directions. In that case, if you cannot buy the new plug, you can level the old one, treat it, after apply a premium sealer; the sealer should be applied on both sides.

Go to the left side, remove vacuum pump,

expansion tank,

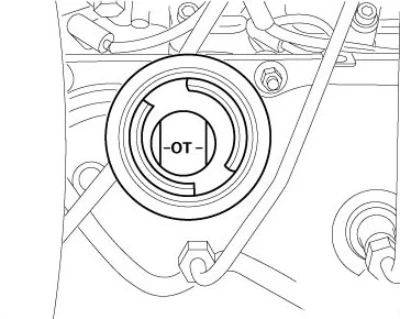

do not forget to install the third cylinder piston at UDC (TDC). For this, first check whether the FROM camshaft label is aligned

with the center of the oil filler. Remove another plug and install the crankshaft lock.

Do not forget to check whether the plug hole aligned with the UDC hole on the crankcheek.

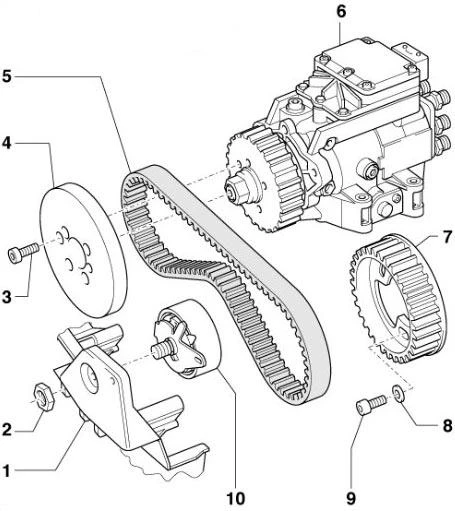

Getting to the removal of fuel pump belt

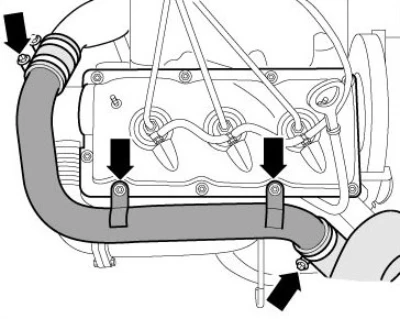

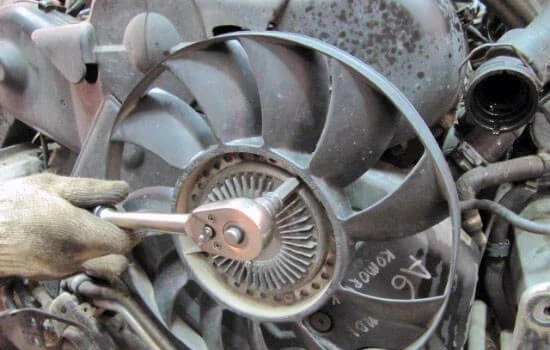

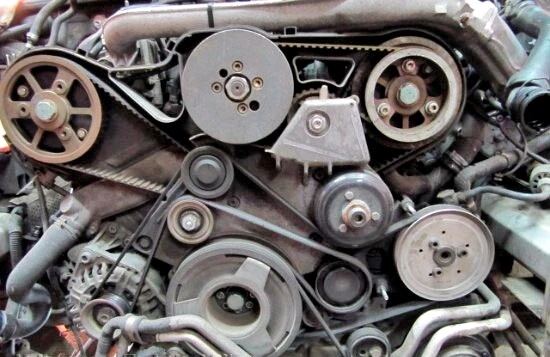

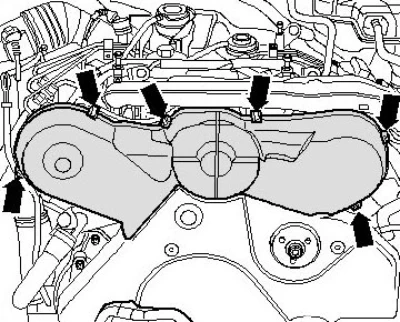

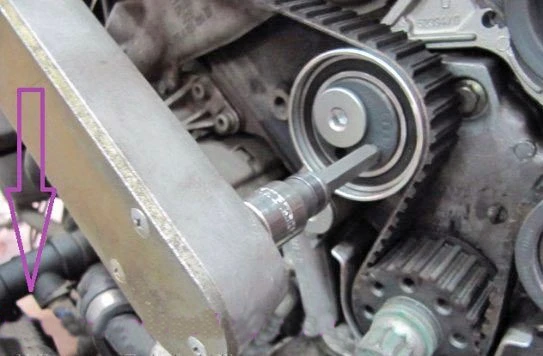

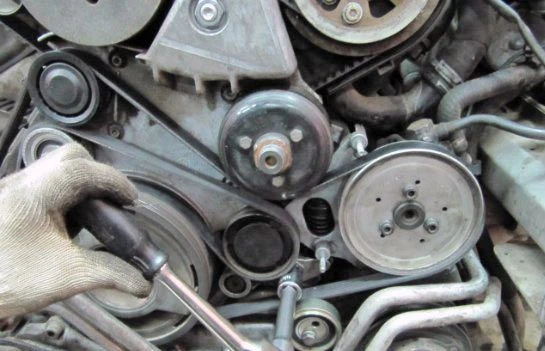

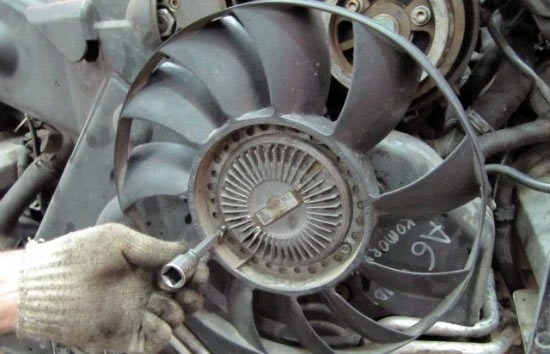

Before you remove the belt is required to remove top timing belt cover, the viscous coupling and fan,

as well as V-belt of hinged part drives, air conditioner V-belt,

Belt tensioner bushing of the cotter belt — weakness in the mechanism

hinged part drive belt cover is also removed.

If you going to put back these belts, you should indicate the direction of their rotation.

Let’s getting started.

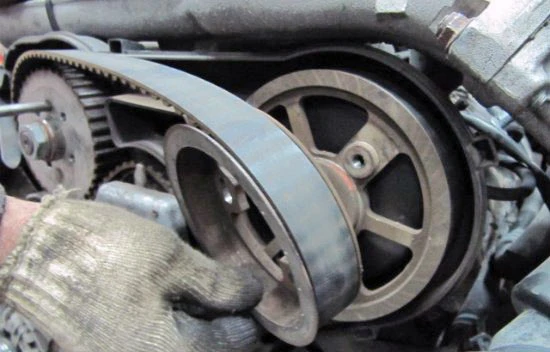

First of all, remove the damper drive of the fuel pump.

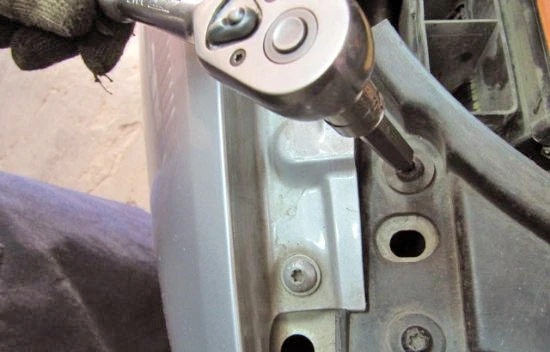

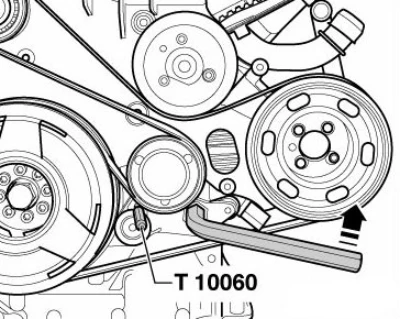

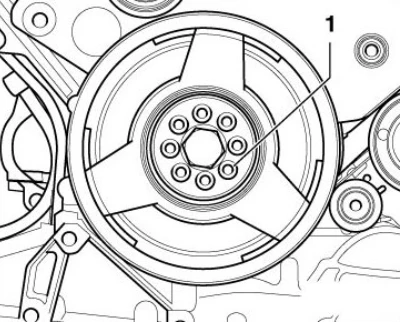

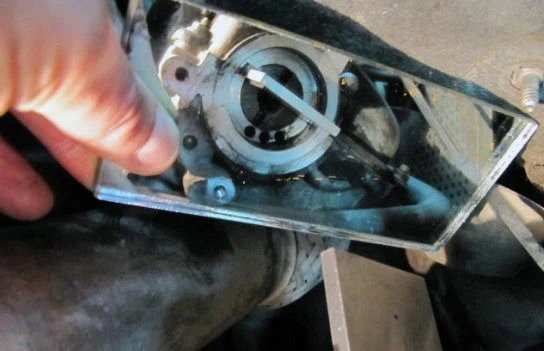

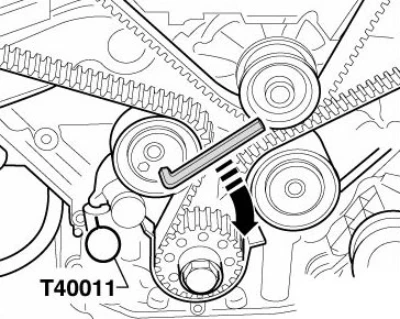

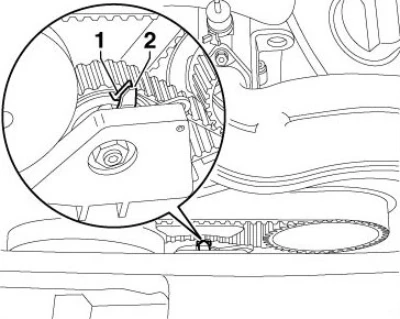

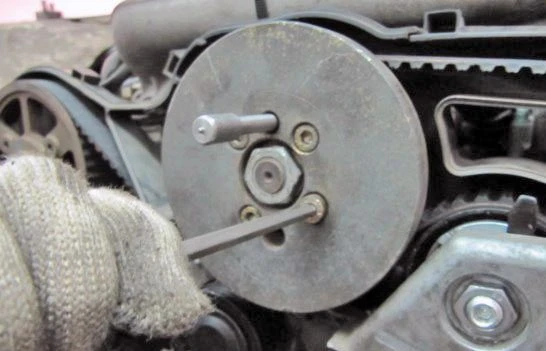

Insert lock #3359 in the fuel pump drive pulley.

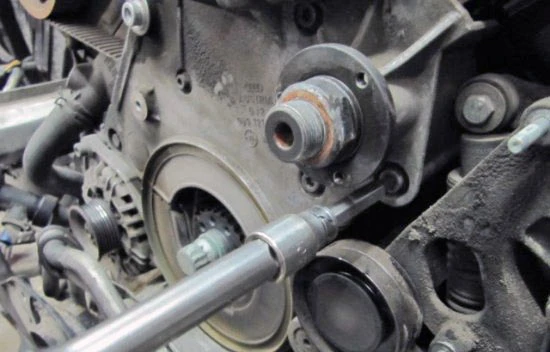

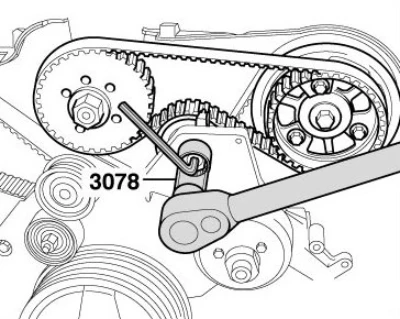

Using nozzle #3078,

loosen the belt tensioner nut. Take a hex key and take the tensioner clockwise, then tighten slightly the tensioner nut.

T-belt Removing Procedure

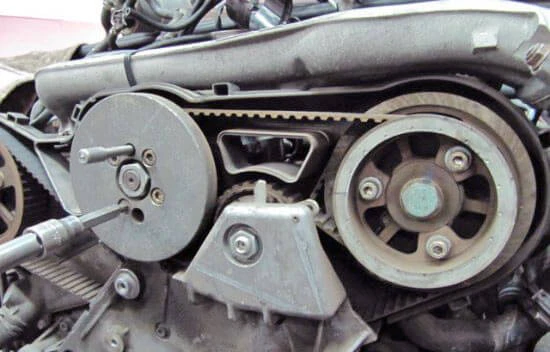

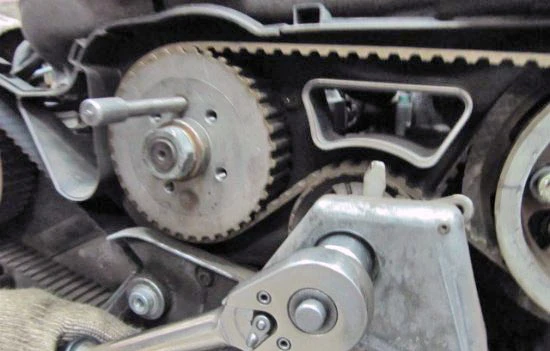

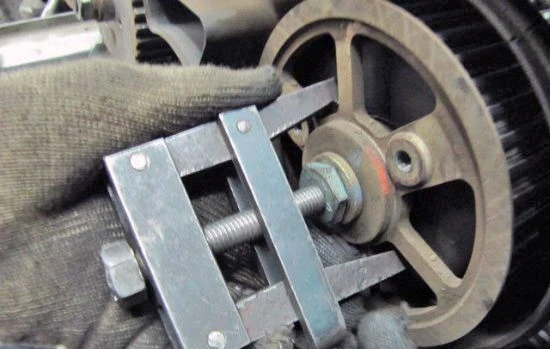

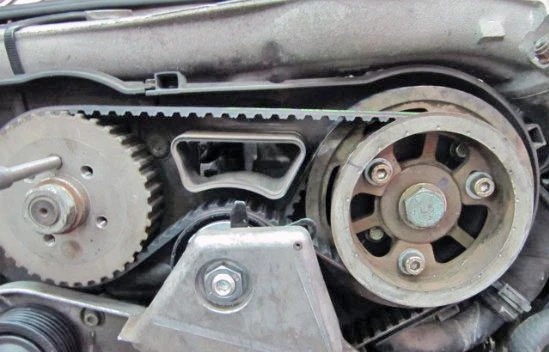

After the pump belt is removed, begin to remove the timing belt. First of all, unscrew the bolts of the left camshaft pulley.

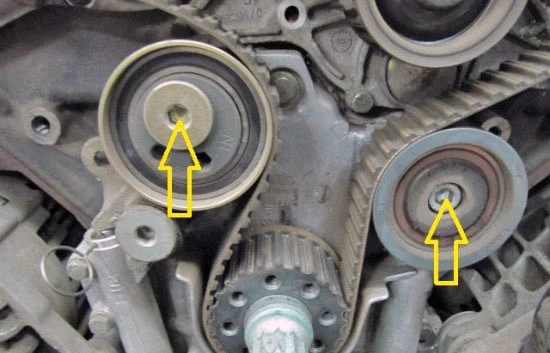

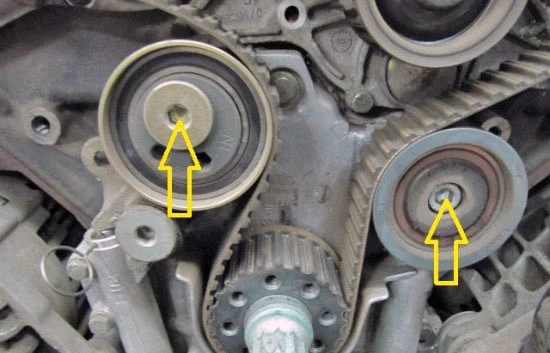

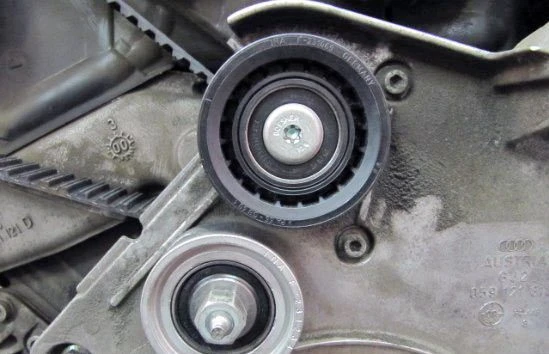

After that, dismantle an external pulley. Carefully inspect the tensioner sleeve, make sure it is in good condition. Functioning sleeve rotates freely in the body, backlash must be completely absent.

Damage to the attachment housing

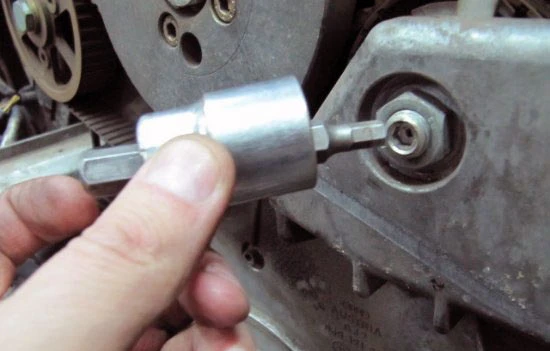

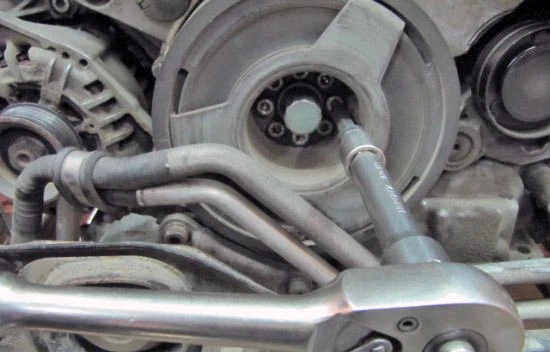

Teflon and rubber O-rings must be undamaged. Now go ahead, you need to loosen the crankshaft pulley bolts.

Remove the crankshaft pulley. Do not unscrew central crankshaft bolt. Hydraulic booster and fan pulleys, as well as the lower timing belt cover must be removed.

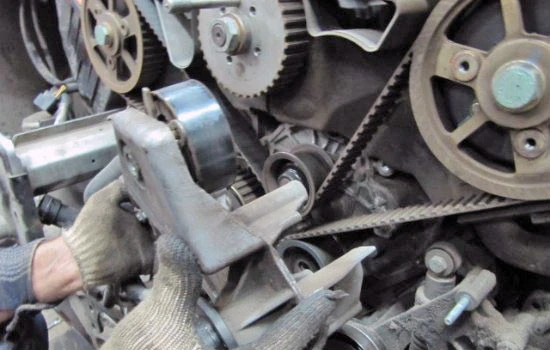

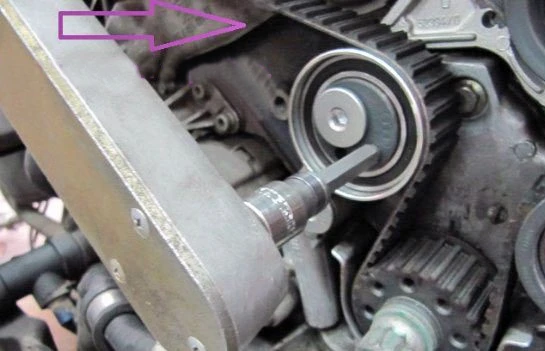

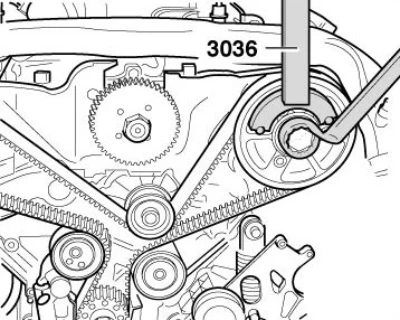

Use lock #3036 to keep the camshaft and loosen pulley bolts of the both shafts.

Take the 8mm hex and rotate the tensioner roller clockwise, as long as the tensioner housing holes and rod holes align.

To avoid damage to the tensioner, do not make too much effort, rotate the roller slowly, with no rush. Fix the rod with 2 mm pin and start to take off intermediate and tension T-belt pulleys,

as well as the T-belt.

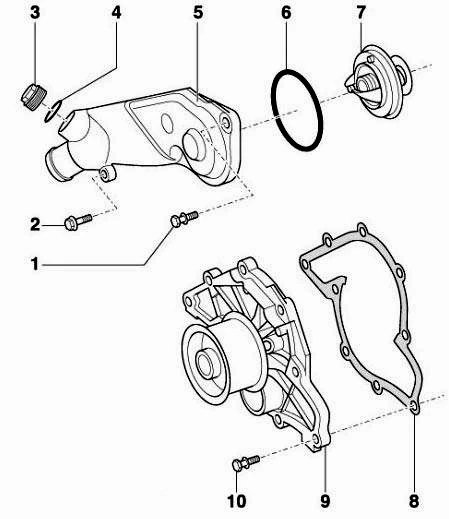

After the removal of pump and timing belts, pay attention to the state of the water pump and thermostat.

All items are to be removed, begin to clean them.

Get to the second part, refitting of the parts.

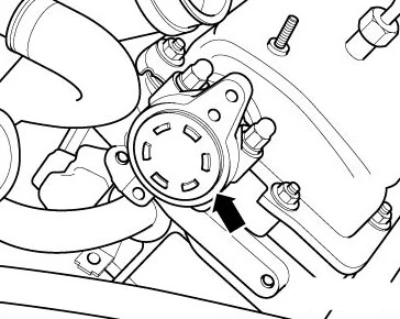

Begin installing the new pump,

before installing, apply the sealant to the pump gasket.

Then, put the thermostat, thermostat housing, apply the sealant to the gasket.

When installing, make sure that the thermostat valve is oriented to 12 hours.

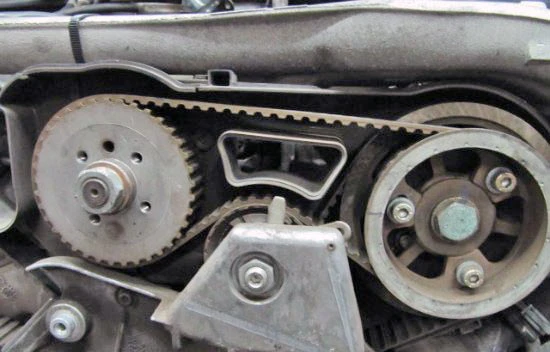

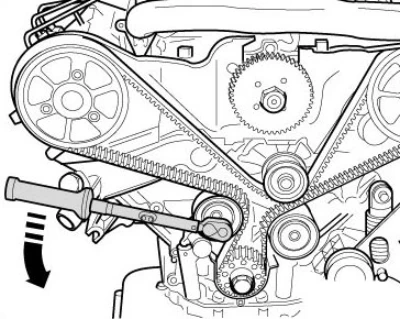

Now, you are ready to install the timing belt. Before installation, make sure that the FROM label is centered on the oil filler.

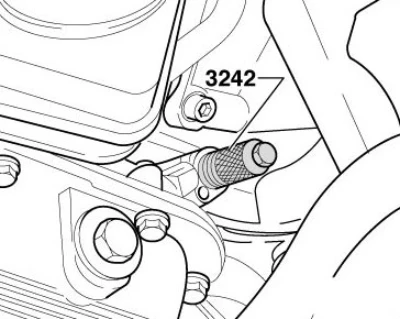

Then, check the proper installation of lock #3242.

Do not forget to check the appropriate position of camshaft locks #3458.

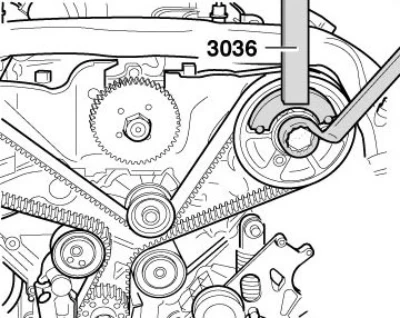

To facilitate the labeling of camshafts for their better rotation, use counter base #3036. Once all labels are exhibited, fix them with releaser #T40001. Do not forget to remove the left camshaft pulley.

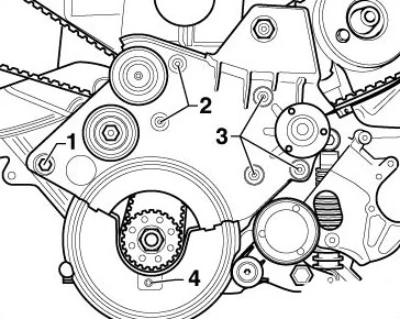

Check the rotation of the right camshaft cogged pulley using the taper fit. If necessary, tighten the bolt by hand. The following step is the installation of the T-belt tension and intermediate rollers,

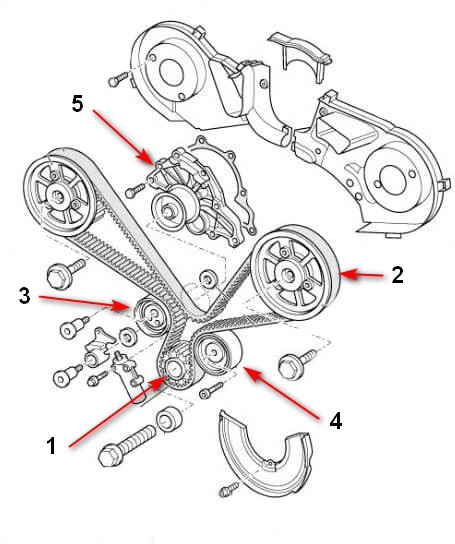

the timing belt is to be installed in the sequence described below:

- Crankshaft.

- Right Camshaft.

- Tensioner Pulley.

- Guide Roller.

- Water Pump.

The left belt string is to be installed on the left camshaft pulley putting them together on the shaft. Then, tighten the center bolt of the left camshaft by hand. Now, check the rotation of the cone grounding pulley, no distortions are prohibited.

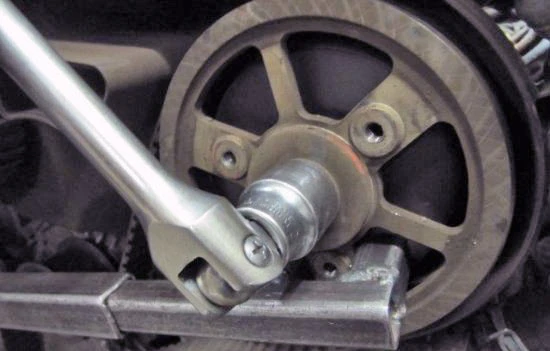

Use the 8 mm hex to turn the tensioner roller clockwise.

clockwise

The tensioner rod lock can now be removed.

Remove the hex, establish there a bilateral torque wrench. Turn the tensioner roller counterclockwise with torque of 15 Nm. That’s all, now you can remove the wrench.

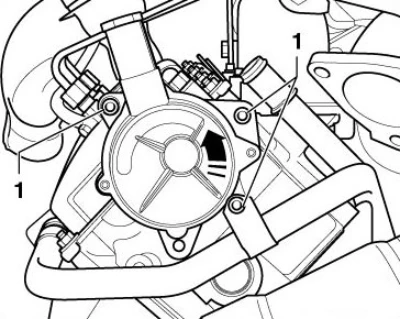

Use #3036 tool to hold the camshaft, tighten the bolts with 75-80 Nm.

Now, you are ready to assemble, put hinged part mounting plate of the V-belts, and fan. Before installing the plate, secure pump belt tensioner roller at the seat, tighten the nut by hand.

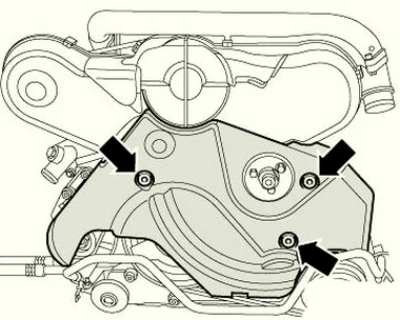

Now, put the lower timing belt cover,

hydraulic booster and fan pulleys.

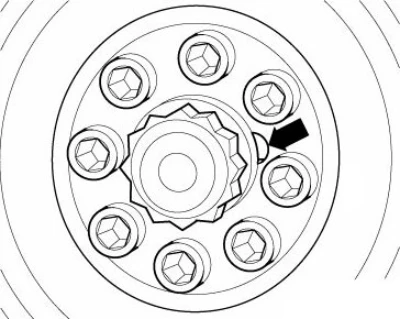

Before installing the crankshaft pulley, align the tabs and notches on the crankshaft gear. The crankshaft cogged pulley bolts must be tightened with torque of 22 Nm.

Getting in high pressure pump belt installing

First, check if the timing marks are installed correctly. Then, put all the rollers on the plate.

Now use a 6 mm hex clockwise to put the pump tensioner pulley in a lower position, tighten the nut by hand.

Done. Now, install fuel pump belt on the camshaft pulley and pump together with the left gear. Be sure that the bolts are located on the center of oval holes. If necessary, you have to crank the gear. Screw the bearing bolts by hand, check the cogged pulley does not rotate freely and there are no distortions.

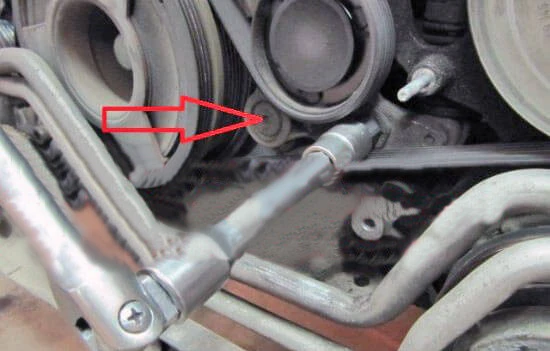

Use tool #3078 to loosen pump belt tensioner nut.

Take the hex key and rotate the tensioner counterclockwise, as long as the target does not align with the check point. After that, tighten the tensioner nut (torque of 37 Nm),

cogged pulley bolts (22 Nm).

Take out the locks and slowly turn the crankshaft twice clockwise. Insert bolt #3242 in the crankshaft. It is advisable to immediately verify the possibility of free installation of pump belt brackets and lock. Once again check the alignment of the check point and target. If they are not aligned, adjust the pump belt tension again. Put the left camshaft vacuum pump, the right camshaft end plug and the engine block plug,

set the pump belt damper,

tighten damper bolts to 22 Nm. No need to immediately install the upper covers of the timing belt, but only if you plan to adjust the start of injection and dynamic test using diagnostic equipment. If you are not going to perform this procedure, you can put the covers. Put the radiator and headlights in place, and connect all electrical equipment,

do not forget to charge the coolant. Start the engine to air out.

How to eliminate “whistle” of the alternator belt

How to eliminate “whistle” of the alternator belt

Repairs of Valeo 90A electric generator

Repairs of Valeo 90A electric generator

Black smoke from car exhaust

Black smoke from car exhaust

Why Is the car battery light on

Why Is the car battery light on